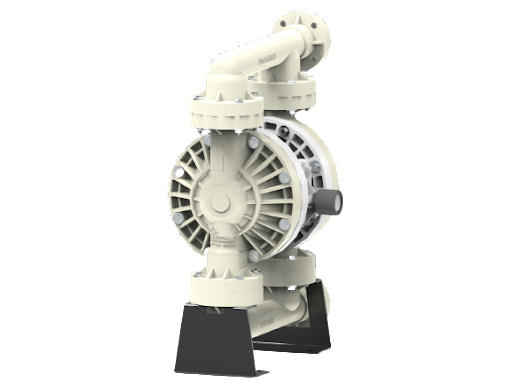

The air-operated diaphragm pumps function across a variety of industries for multiple purposes. Several applications use the AODD pumps, such as rotary lobe pumps, internal gear pumps, peristaltic pumps, external gear pumps, and diaphragm pumps, among many others.

Their performance is impeccable in food, chemical, mining, ceramics, wastewater treatment, coatings, electroplating and anodizing, and pulp and paper industries. In this overview, we have discussed everything about the air operated diaphragm pump.

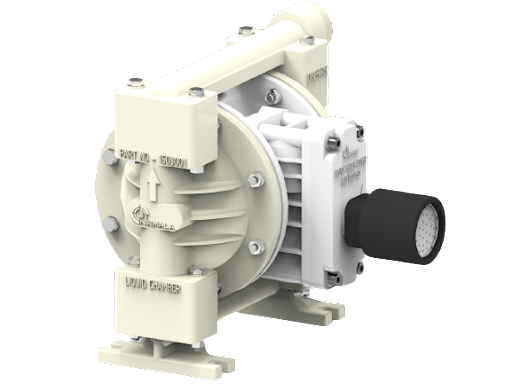

What is an Air Operated Diaphragm Pump?

The diaphragm pumps have a sub-category known as the air-operated double diaphragm pump. In simple terms, the AODD is a type of positive displacement pump that helps pump fluids. A positive displacement pump moves fluid at a fixed speed without changes in pressure to maintain a constant flow. Various sensitive fluids can pass through an AODD pump, such as abrasive and shear fluids, sludges, and slurries.

What are the benefits of the Air Operated Diaphragm Pump?

The air power design of the AODD pump makes it suitable to use around flammable materials. The above-mentioned is just one of the many benefits of the AODD pump discussed in this overview.

- The air-operated diaphragm pumps have sturdy and robust construction. They are low maintenance and cost-effective making them durable for more extended periods. The pump is air-operated, which allows it to run dry without any damage. The air distribution system allows a lubrication-free system that protects the environment from pollution.

- The through control feature allows the air-operated diaphragm pump to operate flexibly and is accessible to adjust according to industrial needs. These pumps are one of the most versatile machines globally that allows uninterrupted and easy flow of fluids. Fluids that are caustic with a high viscosity range are pumped easily through the air-operated diaphragm pump.

- Features like one of the most robust lift capabilities make the air-operated diaphragm pump self-priming. The powerful suction feature allows thick liquids and liquids with solids to pass through the pump with ease. Unlike other pumps, the AODD pump does have pistons, vanes, rotors, or gears to wear it down. This feature allows the pump to run for long periods without significant wear and tear.

- The air-operated diaphragm pump has a design for efficiency. It is adjustable for various liquid discharge and air inlet pressure settings. The primary sources of power for the AODD pumps are Clean Dry Air, filtered air, and Nitrogen. These three components engage their cooling effect while the pump is working, unable to overheat.

- Shear-sensitive liquids like ink or wine can easily pass through the air-operated diaphragm pump without any heat. Just like the process of crushing grapes with feet, the air pumps treat every fluid based on its settings. The constant flow of fluids in the pump has to be maintained by optimal discharge and air pressure. That allows no requirement of a pressure relief pump.

- The air-operated diaphragm pump is flexible, accessible to transport and submersible due to its unique design. It requires no motors, mechanical seals, or coupling to function, making it the world’s most flexible pump. It is effortless to install by connecting the liquid and air supply lines.

- Based on your requirements, the air-operated diaphragm pump is perfect for filter press purposes. When assembled correctly, the AODD pump is explosion-proof while running various fluids.

Types of Air Operated Diaphragm Pump

While the Nirmala Pumps & Equipments – AODD pump is a unique machine with exceptional abilities, various air-operated pumps are available for different industrial purposes. Below are described the types of AODD pumps and their characteristics:

- Rotary Pumps

-

- Gear Pumps

- Screw Pumps

- Positive Displacement Types

-

- Direct drive diaphragm pump – Plunger pumps, Piston pumps, and Bellows pumps

- Hydraulic diaphragm pump

- Air-driven diaphragm pump

- Reciprocating Diaphragm Pumps

- Special Types

-

- Rotary Pumps – Cascade pumps

- Nonpositive Displacement

-

- Centrifugal Pumps – Spiral pumps, Diffuser pumps

- Mixed flow pumps

- Axial flow pumps

Nevertheless, the three broad categories of the pumps are – special types, nonpositive displacement, and positive displacement. The air operated diaphragm pump falls under the positive displacement pump category.

Characteristics of Air Operated Diaphragm Pump

- The AODD pumps are one of the best pumping machines in the market. Their large fluid lifting capacity ensures a constant flow of fluids.

- In addition to the diaphragm pump, the positive displacement pumps transfer fluids like a syringe.

- The fixed fluid volume is transferred through the air-operated diaphragm pump through volume control and using rotational motion.

- The nonpositive displacement pumps function by creating an axial flow. A rotating impeller develops a centrifugal force that helps fluid movement in the AODD pump by applying pressure. Air operated diaphragm suppliers understand the needs of every industry and provide pumps that fulfill those requirements.

What is a Stainless Steel Air Operated Double Diaphragm Pump?

The SS AODD pump is a state-of-the-art bolted type pump. The sealless pump does not require a mechanical shaft making it low-maintenance. AODD pumps rod air motor made of stainless steel ensures corrosion resistance. Manufacturers using ductile iron for chemical processing understand the various benefits of stainless steel. The bolted design of the SS AODD pump is suitable for containing high-value products and raw or finished chemicals.

Common materials used to construct AODD diaphragm pump are Stainless steel, Kynar, Polypropylene, and Hastelloy. Various air-operated Diaphragm pump suppliers offer multiple options to choose from when selecting a pump.

Things to look out for in an Air Operated Diaphragm Pump?

- Make sure the air supply lines are of correct measurements.

- The AODD pump should be placed on a rigid flat base plat at all times to avoid costly repairs caused due to friction.

- Install an air pressure regulator in the pump’s air supply line to control the incoming air pressure, making the installation safe and ensuring constant flow and pressure.

- The suction port should be more oversized in diameter than the fluid inlet suction pipe or hose.

- AODD pumps can be loud while operating and require mufflers to be installed on them. These mufflers are excellent to function in humid and below-freezing temperatures. Nevertheless, it is imperative to check for icing formed in the muffles, which may restrict the pump’s function.

Conclusion

Air-operated Diaphragm Pumps Suppliers provide pumps applicable in almost every industry across the globe. Their various functions allow multiple fluids to pass through with ease and minor damage. The pump can even process or treat flammable liquids due to its air-operated design.