Most burning engines, both spark ignition and compression ignition, operate either a four-stroke cycle or a two-stroke cycle.

1. First Stroke:

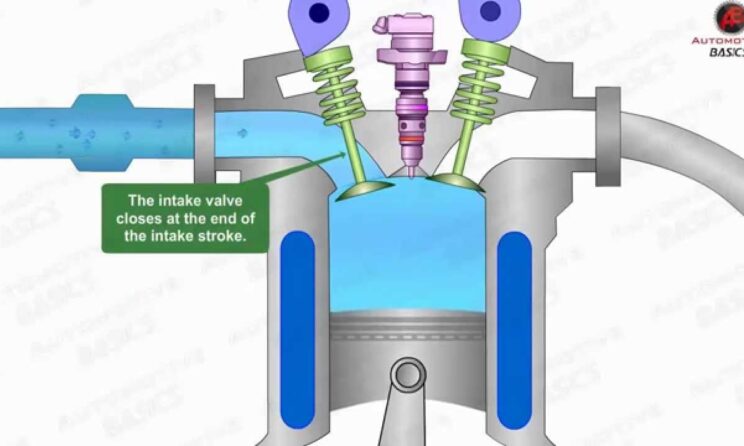

Intake Stroke or Induction The piston travels from TDC to BDC with the valve open and valve closed.

This creates an increasing volume within the combustion chamber, which successively creates a vacuum.

The resulting pressure differential through the intake system from gas pressure on the skin to the vacuum on the within causes air to be pushed into the cylinder.

As the air passes through the intake system, fuel is added to that within the desired amount by means of fuel injectors or a carburetor.

2. Second Stroke:

Compression Stroke When the piston reaches BDC, the valve closes and also the piston travels back to TDC with all valves closed.

This compresses the air-fuel mixture, raising both the pressure and temperature within the cylinder.

The finite time required to shut the valve implies that actual compression doesn’t start until sometime aBDC.

Near the tip of the compression stroke, the plug is fired and combustion is initiated.

3. Combustion

Combustion of the air-fuel mixture occurs in a very very short but finite length of your time with the piston near TDC (i.e., nearly constant-volume combustion).

It starts near the tip of the compression stroke slightly bTDC and lasts into the ability stroke slightly aTDC.

Combustion changes the composition of the gas mixture to it of exhaust products and increases the temperature within the cylinder to a really high peak value.

This, in turn, raises the pressure within the cylinder to an awfully high peak value.

4. Third Stroke:

Expansion Stroke or Power Stroke With all valves closed, the air mass created by the combustion process pushes the piston faraway from TDC.

Because the piston travels from TDC to BDC, cylinder volume is increased, causing pressure and temperature to drop.

5. Exhaust Blowdown

Late within the power stroke, the valve is opened and exhaust blow down occurs. Pressure and temperature within the cylinder are still high relative to the environment at this time, and a pressure differential is formed through the system which is hospitable gas pressure.

This pressure differential causes much of the new exhaust gas to be pushed out of the cylinder and thru the system when the piston is near BDC.

6. Fourth Stroke:

With the valve remaining open, the piston now travels from BDC to TDC within the exhaust stroke.

This pushes most of the remaining exhaust gases out of the cylinder into the system at about air pressure, leaving only that trapped within the clearance volume when the piston reaches TDC.

Near the tip of the exhaust stroke bTDC, the valve starts to open, in order that it’s fully open by TDC when the new intake stroke starts the following cycle. Near TDC the valve starts to shut and eventually is fully closed sometime aTDC.

This period when both the valve and valve are open is named valve overlap.

Four-Stroke CI Engine Cycle

1. First Stroke: Intake Stroke the identical because the intake stroke in an SI engine with one major difference: no fuel is added to the incoming air.

2. Second Stroke: Compression Stroke the identical as in an SI engine except that only air is compressed and compression is to higher pressures and temperature.

Late within the compression stroke fuel is injected directly into the combustion chamber, where it mixes with the highly regarded air.

This causes the fuel to evaporate and self-ignite, causing combustion to start out. 3. Combustion: Combustion is fully developed by TDC and continues at about constant pressure until fuel injection system is complete and therefore the piston has started towards BDC.

4. Third Stroke: Power Stroke the ability stroke continues as combustion ends and also the piston travels towards BDC. 5. Exhaust Blowdown Same like an SI engine. 6. Fourth Stroke: Exhaust Stroke Same like an SI engine.

Two-Stroke SI Engine Cycle

1. First Stroke: Expansion Stroke or Power Stroke Very high created by the combustion process forces the piston down within the power stroke.

The expanding volume of the combustion chamber causes pressure and temperature to decrease because the piston travels towards BDC.

2. Exhaust Blowdown At about 75° bBDC, the valve opens and blowdown occurs.

The valve is also a valve within the plate, or it should be a squeeze the side of the cylinder which is uncovered because the piston approaches BDC.

After blowdown the cylinder remains stuffed with exhaust gas at lower pressure.

3. Intake and Scavenging When blowdown is sort of complete, at about 50° bBDC, the intake slot on the side of the cylinder is uncovered and intake air-fuel enters fraught.

Fuel is added to the air with either a carburetor or mechanical system.

This incoming mixture pushes much of the remaining exhaust gases out the open valve and fills the cylinder with a combustible air-fuel mixture, a process called scavenging.

The piston passes BDC and extremely quickly covers the intake port then the exhaust port (or the valve closes).